NANO EMULSIONE ACQUA-CARBURANTI

WIFNE

Per visionare alcune delle esperienze effettuate dal personale in AVKEM è possibile accedere al link CASE HISTORY

GENERATION OF NANO EMULSION LOWER THAN 2µ

Water-fuel emulsions are known processes but little used due to the residual size of the water droplets which is never less than 2 µ.

AVKEM® is currently the only company able to produce:

- online water emulsions with any type of fuel, even viscous, of hydrocarbon, vegetable and animal fat, with micelles size less than 0.2 µ;

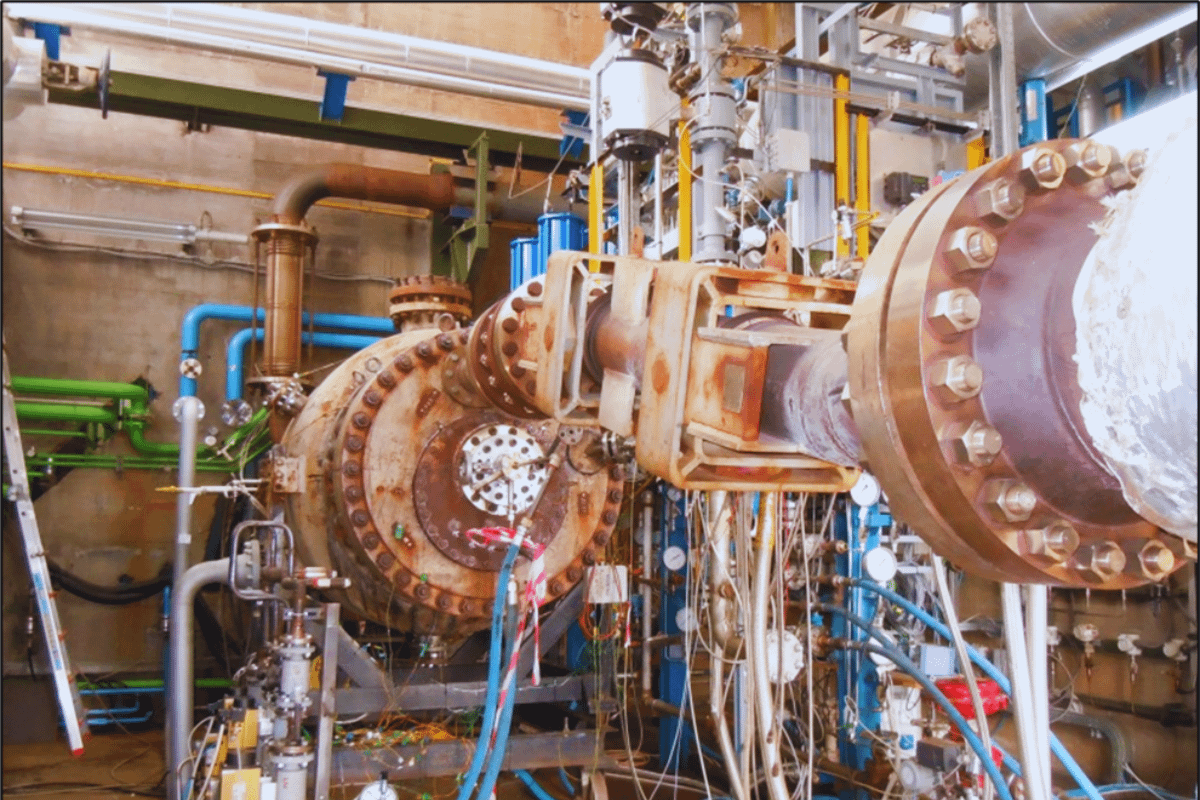

- emulsifying machines, designed and manufactured by AVKEM® with proprietary management software

- specific additives formulated and tested by AVKEM®

We examined the water micelles with a Coulter Counter, and they were found to have the following dimensions:

- Average particle size 400 nm

- Maximum size 900 nm

- Percentage of particles < 1000 nm = 90%

WATER IN FUEL NANO EMULSION

AVKEM NANO-Emulsions, with the specific additives allowe to improve the fuels quality, even particularly heavy and viscous, allowing to generate blends of products that could not be burned individually.

This makes it possible to expand the range of fuels that can be used, especially those at low cost (generally characterized by low calorific value, higher acidity and impurity content), generating savings both on fuels and on the treatment of emissions.

This is not possible with micro-emulsions.

Here are some comparative photos of micro and nano emulsions made under the microscope and in the laboratory where the advantage of NANO dimensions is evident.

NANO EMULSION

MICRO EMULSION

NANO /MICRO EMULSION

A classic emulsifier must recycle the emulsion several times (usually 3 to 4 times) the dimensions of the micelles are ≥ to 2µ, and the homogeneity, obtainable only with the NANO dimensions of the micelles, always requires a greater quantity of additive.

The NANO-Emulsions can feed different types of machines for the generation of heat and energy, for which we can add the following quantities of water, in consideration of the respective efficiency curves:

- Stationary endothermic engines between 12% and 18%

- Boiler between 24% and 35%

- Gas turbines over 50%

- reduce the additive to a minimum of 0.1%

- improve combustion

- reduce the viscosity

- change online the fuel composition

- choose fuel savings or the quality of emissions, depending on the needs of customers, by varying the amount of water in the emulsion

- adapt the emulsion to the type and state of wear of the machines, within the limits imposed by them and by the fuel.

- a guaranteed economic saving of 2% and an effective savings found by customers between 4% – 6%

- a significant reduction in emissions without the increase in CO and CO2:

- significant reduction in the size of the SCR filters (< 50%)

- savings on maintenance to be evaluated from time to time depending on the condition of the machines and filters.